Introduction

Motor vehicle repair is an essential industry that keeps our cars, vans and lorries running smoothly. Whether it’s routine maintenance, minor repairs, or major overhauls, automotive technicians play a critical role in maintaining the safety and functionality of our vehicles. However, amidst the constant hustle and bustle of repair shops, it is paramount to prioritize health and safety measures. This article delves into the significance of health and safety in motor vehicle repair and highlights essential practices for a secure working environment.

The Importance of Health and Safety

- Protecting Workers: Automotive repair can expose technicians to various hazards such as chemical exposure, physical injuries, ergonomic strains, and even noise pollution. By prioritizing health and safety, employers can create a workplace that protects the well-being of their technicians, reducing the risk of accidents, injuries, and long-term health issues.

- Minimizing Liabilities: Neglecting health and safety protocols can result in costly legal implications for repair shop owners. Complying with established regulations not only protects the workforce but also safeguards businesses from potential lawsuits, insurance claims, and reputational damage.

Key Health and Safety Practices in Motor Vehicle Repair

- Training and Education: Employers must provide comprehensive training programs that cover safety protocols, handling of hazardous materials, proper tool usage, and equipment maintenance. Regular refresher courses should be conducted to keep employees updated on the latest safety standards and best practices.

- Personal Protective Equipment (PPE): Technicians should be equipped with appropriate PPE, including safety goggles, gloves, protective clothing, and respiratory masks. PPE acts as a barrier against chemical splashes, harmful fumes, sharp objects, and other potential risks.

- Hazard Communication: Repair shops should establish clear communication systems to inform employees about the potential hazards associated with specific tasks, chemicals, or equipment. Material Safety Data Sheets (MSDS) should be readily accessible to provide crucial information on safe handling and storage of hazardous substances.

- Proper Ventilation: Adequate ventilation is crucial to prevent the accumulation of toxic fumes and ensure good indoor air quality. Repair facilities should have well-designed ventilation systems to remove exhaust gases, paint fumes, and airborne particles effectively.

- Safe Lifting and Ergonomics: Automotive repair often involves heavy lifting and repetitive motions, which can lead to musculoskeletal disorders. Employers should promote safe lifting techniques and provide mechanical lifting aids whenever possible. Ergonomic workstations and adjustable tools can also help reduce strain on technicians’ bodies.

- Equipment Maintenance: Regular inspection, maintenance, and calibration of tools and equipment are vital to ensure their safe and efficient operation. Defective or malfunctioning equipment should be promptly repaired or replaced to prevent accidents and injuries.

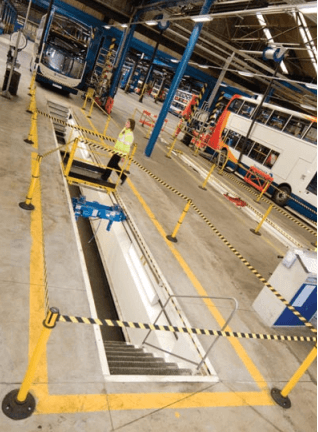

- Housekeeping and Cleanliness: A clean and organized work environment minimizes tripping hazards and promotes overall safety. Regular housekeeping practices, such as keeping floors clean, removing clutter, and promptly addressing spills or leaks, contribute to accident prevention.

- Emergency Preparedness: Repair shops should have well-defined emergency response plans in place, including procedures for fire safety, first aid, and evacuation. Employees should receive training on emergency protocols and the location of emergency exits, fire extinguishers, and first aid kits.

Conclusion

Prioritizing health and safety in motor vehicle repair is not only a moral obligation but also a legal and financial imperative. By implementing robust safety practices, repair shops can protect their employees, mitigate liabilities, and foster a positive working environment. A commitment to health and safety ensures that automotive technicians can carry out their crucial work with confidence, knowing they are supported by a culture that values their well-being and takes every necessary precaution to prevent accidents and injuries.

The HSE provide a free document, HSG 261 for Motor Vehicle Repair and Associated industries.

Complisafe are able to provide this sector with a number or services such as training, risk assessments, inspections and audits.

How Complisafe can help…

Our Health and Safety Inspections are a “moment in time” monitoring process conducted by our health and safety consultants. We are looking for existing and potential hazards as well as coaching people in the process. We identify solutions that are practical and effective so we are not just identifying problems. Where good management, controls and behaviour are identified these are also documented in the inspection.

Our health and safety inspections are carried out by our skilled, knowledgeable, experienced and competent health and safety consultants. Inspections start with a brief meet and catch up with the manager or supervisor and where relevant a review of the outstanding items from the last inspection.

We will inspect the site/premises/environment as well as observing work in progress and activities taking place at the time, we will engage with workers and where required ask for any unsafe activities or tasks to be stopped to prevent injury or ill health. We will also check documentation, competencies, risk assessments and methods of work that are appropriate for that inspection. We will also discuss future planned works before summarising the inspection with the manager/supervisor. A written inspection report is then provided with an action plan.

Our Health and Safety Audits are carried out in person by using a number of approaches to gauge a true reflection on where your business is, in terms of compliance. We will audit against your existing arrangements and procedures, policies, industry standards and current legislative requirements. We will need to speak to a selection of employees at varying levels, including leadership, through short interviews. We will review documentation including assessments, policies, training records, checks, tests and inspections and most importantly how we will want to see how health and safety works by looking at premises, activities and behaviours. The Audit is then presented back to you along with an action plan that has clear priorities for you to take away and action.

We can deliver training face to face in large or small groups, we can also utilise online systems such as teams and zoom. All sessions involve interaction, input and participation by attendees and can include practical situational scenarios, breakout exercises and use of the workplace environment where necessary. We deliver most sessions in a half day to ensure attention is maintained, time efficient and to avoid information overload, we utilise various tools including presentations by our trainers as well as videos and practical exercises.

With more flexible working arrangements it’s a great way of getting people trained efficiently online. Our training offers engaging, interactive, person presented training with questions, tests and certification with the majority only taking forty minutes to complete. We also provide your team or team members with an admin portal so you can see who has or has not started or completed the training, send reminders, access certificates and allocate training to users. This also includes simple branding and gives you control over your training and reporting. Alternatively you can simply ask us to manager this for you if you only have small numbers requiring training. The quality of our training system is something we have 100% confidence in and it can be trialled before you commit so you can see for yourself.

One of the key areas of Health and Safety for employers is the provision to employees of health and safety information, instruction and training. It’s very important that this knowledge is absorbed and remembered and our training courses are engaging and easy to follow to ensure a great learning experience is had. Our training gives you confidence that employees have been given awareness training and that they have understood this information by being tested on the training module and then issued a certificate.

Training is also a legal requirement and whilst online training is not suitable for certain subjects and certification, it’s great for awareness and reaching staff wherever they are and whatever device they are using.

Our approach to provide competent advice and support is to understand firstly what you do and the type of support you need. Every business is different but we are very experienced in working out what type of support and guidance you may require and we take pride in our honest and practical advice. Some clients may only contact us a handful of times throughout the year and some will speak to us every week! Once engaged with Complisafe Health and Safety Consultants we are available to answer questions and take calls on all things Health, Safety, Fire and CDM. We issue you with a certificate that can be displayed at your workplace and shared with clients that confirms the relationship with Complisafe and your business.