Prosecutions | Statistics | Display Screen Equipment training and Assessment Offer

HSE Prosecutions

Property owner sentenced as works were for his business and therefore CDM applied.

A Derbyshire property owner has been given a community order after a father-of-two sustained life changing injuries when a wall collapsed on top of him during a barn conversion.

Nigel E. failed to have a structural assessment of the outbuildings carried out as part of his planning for the project at his home in Woodhouses. The outbuildings were being converted into holiday let accommodation when a stone wall collapsed on 40-year-old Steven T on 8 October 2021.

The married father of two daughters from Melbourne, suffered a catalogue of serious injuries, including a fractured skull, a bleed on the brain and multiple broken bones, including 11 of his ribs. He was rushed to hospital, where he spent the next 18 days in “immense pain”.

He said: “The pain was made worse by the fact I was unable to see my daughters in hospital due to the Covid-19 restrictions on visitors.

“I am still in pain today and struggle to put weight on my right ankle.

“Due to the traumatic head injury, I was unable to drive for six months.”

Derby Magistrates Court heard how the building had undergone significant structural alterations. It was while Mr T. was clearing up outside, that the external face of the stone gable wall collapsed on top of him causing life threatening injuries.

An investigation by the Health and Safety Executive (HSE) found that Nigel E. had failed to have a structural assessment of the outbuildings undertaken prior to starting the work. As a result, no measures had been identified or implemented to stabilise the building while underwent the alteration. Similarly, there was no plan in place for dismantling parts of the building safely, exposing workers and members of the public to the risk of injury or death from the full or partial collapse of the structures.

Mr T, who has been left blind in one eye as well as losing hearing in his right ear, went on to say how the incident had left him unable to work in the construction industry.

“I might never be able to,” he added.

“The injuries have also impacted on my hobbies, which included karate, dog walking and metal detecting.

“I have also had therapy sessions to try and come to terms with the physical and psychological impacts of what happened.

“This is something I thought I would never have to do.”

Nigel E of Tutholme, Woodhouses, Melbourne, Derbyshire, pleaded guilty to breaching Regulations 19(1) and 20(1) of the Construction (Design and Management) Regulations 2015. He was made the subject of a 12-month community order and told to complete 80 hours of unpaid work. He must also pay costs of £4,097.94.

Speaking after the hearing, HSE inspector Robert Gidman said: “It is vital that all demolition and dismantling is adequately planned and that a competent structural engineer is engaged by those in control of work where there is the risk of collapse of any structure.

“If this project had been planned effectively, engaging the right people at the right time to ensure a suitable safe system of work was implemented, the life changing injuries sustained by the injured person could have been prevented.”

Company fined as worker sufferers brain trauma

A London company has been fined £175,000 after a worker suffered serious head injuries that saw him hospitalised for seven months.

The man, who was 35 at the time, was working at a domestic property on Elmfield Avenue, Crouch End, London, on 3 March 2019 when he sustained head injuries during concrete pumping operations carried out by sub-contractor Singh Will Mix It Ltd.

A concrete pump operator was cleaning the pump’s hose after it had been used to pump concrete for a ground floor extension at the property. As the pump operator was doing this, the pump became blocked, leading to a sudden release of pressure and causing the hose to whip and strike the worker in the head. The pump operator was not qualified to operate the machine.

The injured worker spent seven months in hospital following the incident, suffered brain trauma, and continues to have difficulties with his speech, memory and movement.

An investigation by the Health and Safety Executive (HSE) found Singh Will Mix It Ltd failed to ensure workers had the necessary skills, knowledge, experience and training to carry out the work and they failed to have appropriate health and safety systems in place to carry out the work safely.

Singh Will Mix It Ltd, of Larkshall Road, Walthamstow, London, was found guilty of breaching Sections 2(1) and 3(1) of the Health & Safety at Work etc. Act 1974 following a trial at Southwark Crown Court. The company was fined £175,000 and ordered to pay £75,722 in costs at Southwark Crown Court on 15 March 2023.

HSE inspector Gordon Nixon said: “HSE will not hesitate in prosecuting where contractors and operatives do not have the appropriate skills, knowledge, experience and training when carrying out dangerous tasks and putting people at risk.”

Hereford Company receives £190K fine

A Hereford company has been fined £190k after an employee was seriously injured after falling into a pit.

The man was working for Wyman-Gordon Limited, a company that produces forgings for the aerospace industry, when he fell into the bottom of a pit on 25 November 2018. He sustained deep cuts to his head that required eight stitches. He had been working at the company’s premises on Spa Road, Lincoln.

While changing an oil seal on a counterblow hammer, a lifting sling containing a 169kg load broke. The load fell and broke the board the worker was standing on, causing him to fall into the bottom of the pit.

The man has revealed how the incident left him feeling anxious after returning to work.

The worker said in his victim impact statement: “I was on sick leave for three weeks.

“After the accident I became more anxious while doing high risk work. I continue to have a problem with my back. I go to physiotherapy via the NHS when necessary. Currently, it has become difficult for me to get up in the morning because of my back.

“I also have frequent headaches. I have been to different hospitals in connection with that, but no cause has been determined.

“Also the accident had a partial impact on looking after my wife as I could not lean forward and bend down for about two weeks. My daughter had to assist both me and my wife during all that time.”

An investigation by the Health and Safety Executive (HSE) found Wyman-Gordon Limited failed to ensure so far as is reasonably practicable, the health, safety and welfare at work of its employees during the ram seal replacement. There was no safe system of work that properly addressed work at height and lifting operations. The company should not have lifted loads over employees and either prevented the need to work at height, or used alternative methods for doing so. HSE guidance on equipment and machinery can be found at: Equipment and machinery – HSE

Wyman-Gordon Limited, of Holmer Road, Hereford, Herefordshire, pleaded guilty to breaching Section 2(1) of the Health and Safety at Work etc Act 1974. The company was fined £190,000 and ordered to pay £35,000 in costs at Lincoln Magistrates’ Court on 16 March 2023.

HSE inspector Stacey Gamwell said: “Employers have a responsibility to devise safe methods of working that properly address the risks, had one been in place prior to the incident, the injuries sustained by the employee could have been prevented. There is guidance freely available on the HSE Website regarding the safe planning, organisation and undertaking of lifting operations. Guidance is also freely available in relation to working at height safely.”

Health and safety statistics

Key figures for Great Britain (2021/22)

- 1.8 million working people suffering from a work-related illness, of which

- 914,000 workers suffering work-related stress, depression or anxiety

- 477,000 workers suffering from a work-related musculoskeletal disorder

- 123,000 workers suffering from COVID-19 which they believe may have been from exposure to coronavirus at work

- 2,544 mesothelioma deaths due to past asbestos exposures (2020)

- 123 workers killed in work-related accidents

- 565,000 working people sustained an injury at work according to the Labour Force Survey

- 61,713 injuries to employees reported under RIDDOR

- 36.8 million working days lost due to work-related illness and workplace injury

- £18.8 billion estimated cost of injuries and ill health from current working conditions (2019/20)

Complisafe Provide DSE training and assessment online

If workers use display screen equipment (DSE) daily, as part of their normal work, continuously for an hour or more, employers must do a workstation assessment.

Employers should look at:

- the whole workstation, including equipment, furniture, and work conditions

- the job being done

- any special requirements of a member of staff, for example a user with a disability

Where there are risks, they should take steps to reduce them.

Employers must also do an assessment when:

- a new workstation is set up

- a new user starts work

- a change is made to an existing workstation or the way it’s used

- users complain of pain or discomfort

The law says employers must plan work so there are breaks or changes of activity for employees who are display screen equipment (DSE) users.

There is no legal guidance about how long and how often breaks should be for DSE work. It depends on the kind of work you are doing. Take short breaks often, rather than longer ones less often. For example 5 to 10 minutes every hour is better than 20 minutes every 2 hours. Ideally, users should be able to choose when to take breaks.

In most jobs it is possible to stop DSE work to do other tasks, such as going to meetings or making phone calls. If there are no natural changes of activity in a job, employers should plan rest breaks.

Breaks or changes of activity should allow users to get up from their workstations and move around, or at least stretch and change posture.

Eyes and eyesight testing

The law says employers must arrange an eye test for display screen equipment (DSE) users if they ask for one, and provide glasses if an employee needs them only for DSE use.

DSE work does not cause permanent damage to eyes. But long spells of DSE work can lead to:

- tired eyes

- discomfort

- temporary short-sightedness

- headaches

DSE work is visually demanding, so it can make someone aware of eyesight problems they have not noticed before (including changes in eyesight that happen with age).

Employees can help their eyes by:

- checking the screen is well positioned and properly adjusted

- making sure lighting conditions are suitable

- taking regular breaks from screen work

Employers must assess DSE workstations and take steps to reduce any health risks.

Eye tests for DSE users

An employer must provide an eyesight test for a DSE user if they request one. The employer must also pay for the test.

This should be a full eye and eyesight test by an optometrist or doctor, including a vision test and an eye examination.

It’s up to the employer how they provide the test. For example, they could let users arrange the tests and reimburse them for the cost later, or they could send all their DSE users to one optician.

Glasses for DSE work

Employers only have to pay for glasses for DSE work if the test shows an employee needs special glasses prescribed for the distance the screen is viewed at. If an ordinary prescription is suitable, employers do not have to pay for glasses.

Training and information

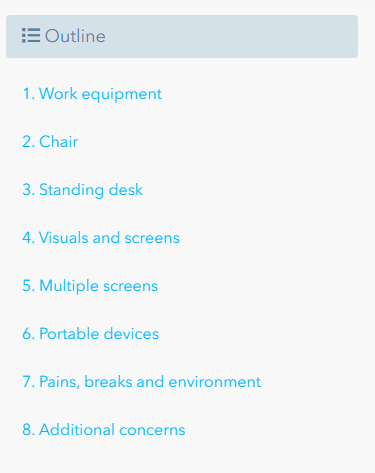

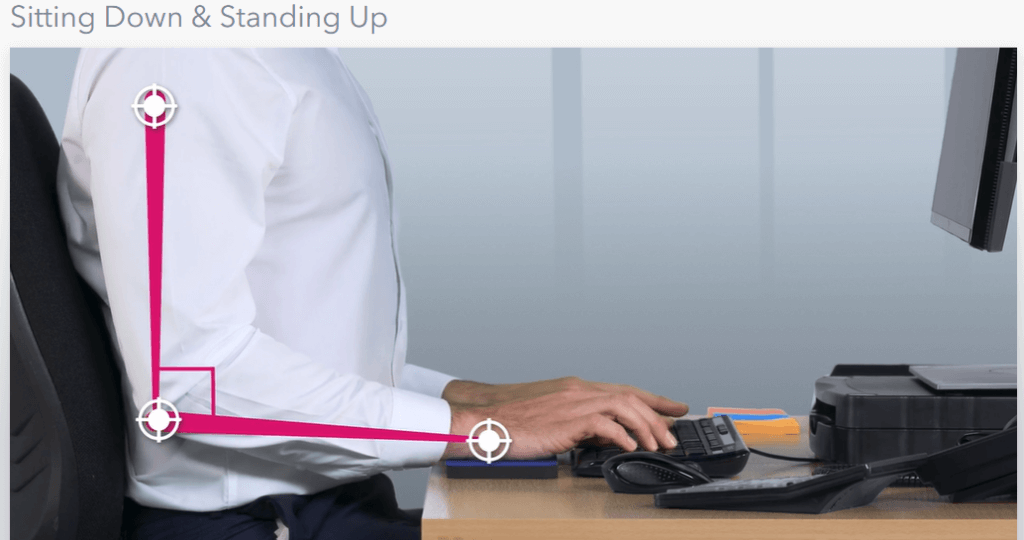

Employers must provide health and safety training and information for display screen equipment (DSE) users. Training should be about the risks in DSE work and how to avoid these by safe working practices. It should include:

- good posture

- adjusting chairs and other furniture

- arranging desk space

- adjusting screens and lighting to avoid reflections and glare

- breaks and changes of activity

- risk assessments

- how to report problems

Employers should also tell users about the general arrangements they have made for health and safety in their DSE work, and how they can apply for an eye test.

Working with display screen equipment at home

The Health and Safety (Display Screen Equipment) Regulations can apply to workers who:

- work at home on a permanent or long-term basis

- routinely split their time between their workplace and home (sometimes called hybrid working)

Your workers are display screen equipment (DSE) users if they work on DSE daily, for continuous periods of an hour or more. You should check if the DSE regulations apply to your workers.

The regulations don’t apply to workers who use DSE occasionally or only for short periods of time at home.

DSE risk assessment

Where the regulations do apply, you should carry out a DSE assessment for individual workers. In most cases you do not need to visit them to carry out the assessment, unless you decide there is a need to do so. Your workers may complete a self-assessment provided they have been given suitable training, for example by explaining how to use an ergonomic checklist or self-assessment tool.

There is a practical DSE workstation checklist that may help you to make a simple DSE assessment and record and communicate the findings.

Where workers use DSE in the home and office, the assessment should cover both situations.

Make sure those working at home can achieve a comfortable, sustainable posture. They may not need office furniture or equipment at home to achieve this. But you should check if their own equipment is suitable.

Managing the risks

Make sure that you can implement the findings of your assessments for your workers using DSE at home.

Reduce the risks identified by your assessment so far as reasonably practicable. This means balancing the level of risk against the measures needed to control the real risk in terms of money, time or trouble.

Where your DSE workstation assessment indicates you need to take some action, for example providing a piece of DSE equipment, your workers cannot be charged for this.

Keep your DSE arrangements under review, particularly if there have been significant changes.

Check if your existing control measures are sufficient or whether additional steps are needed, for example where your workers report aches, pains or discomfort.

Additional DSE equipment needs

Use your assessment to decide if people need any additional equipment when working at home.

Alongside information provided by the worker, you may need to ask for competent advice. For example, from:

- a suitably trained DSE assessor

- suitable occupational health professional

You should meet additional individual needs so far as reasonably practicable.

DSE information and training

You must provide workers with training in the use of their workstation and DSE equipment. This should include advice on achieving good posture, and on good working practices.

Work routine and breaks

The law says employers must plan work so there are breaks or changes of activity for workers.

Display Screen Equipment Training and Display Screen Equipment Assessment for £15+VAT per person with our high quality approved on line training. Modern, engaging and informative.

As you work through the training and assessment the learning management system provides advice and tips to help close out issues and when to seek further help.

Complisafe Health and Safety On line training has over 150 courses available.